Surface of the workpiece must be made suitable for roller burnishing. For this, pre-machining is advised. Pre-machining is necessary for getting standard and good surface quality after roller burnishing. As pre-machining lathe, reaming, grinding or etc. processes can be applied.

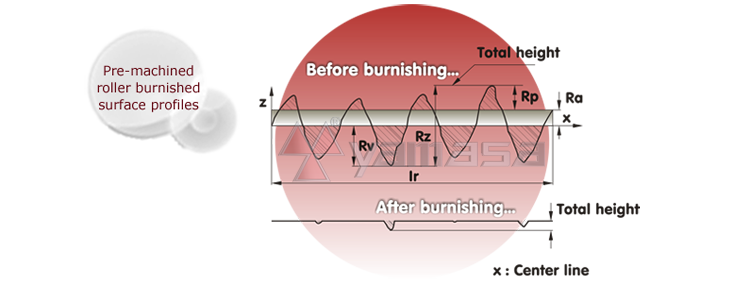

On the workpiece, stock allowance is left for roller burnishing. Pre-machining is applied by considering this stock allowance. Roller burnishing doesn’t pull off a piece from surface, only accumulates roughnesses of the surface on to each other,in this context we can say that generally roughness depth determines the stock allowance. Stock allowance equals to roughness depth (Rz). Thus, on the workpiece, stock allowance is left as roughness depth.

After pre-machining roughness depth must be between Rz = 5 - 30 µm (max. 5 - 50 µm) according to diameter and material type.

Before roller burnishing to obtain the most appropriate surface, you can use the lathing formula below;

Feed rate per revolution (mm/rev.) = 0.5 x cutter edge radius (mm)

The workpiece after pre-machining becomes ready for roller burnishing process. After the roller burnishing process, there is no roughness left on the surface (see figure).

Bu sayfaya girebilmeniz için 18 yaşından büyük olmanız gerekmektedir.

18 yaşından büyük müsünüz?

You have to be over 18 to enter this page.

Are you over 18?