Application

YAMASA DX type tools are used for the aim of burnishing the cylindrical holes that have an open and closed end. The tools provide as well as surface hardness and calibration (measurement accuracy) beside of burnishing.

-

Used on all kinds of machining production machines such as CNC and universal lathe, machining centers, drilling or milling machines, etc.

-

Pre-machining and burnishing is possible on same machine. Process is done in one pass after pre-machining.

-

Because of the high processing power and speed ability it provides time saving. These are the preference causes for the serial production.

Tool Versions

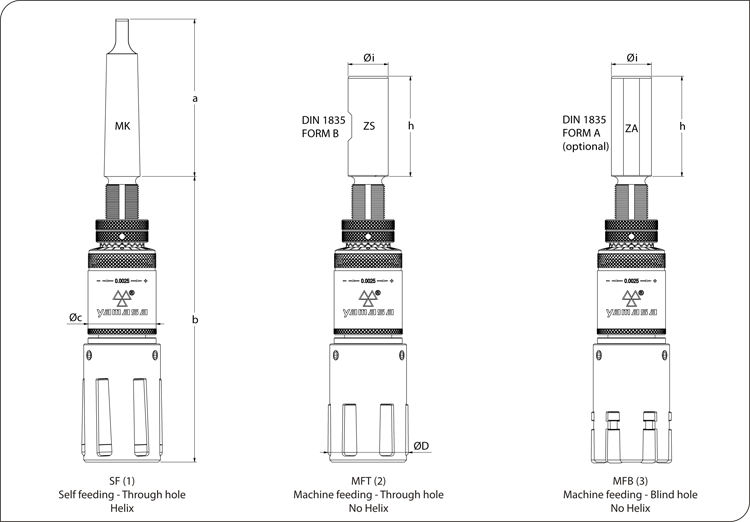

There are three versions of YAMASA DX roller burnishing tools according to the process type.

Version 1: Self feeding for through holes (SF)

- Burnish the through holes.

- It is suitable for use such on universal lathe, drilling, milling machines.

- It makes the feeding self. If the revolution is increases the feeding speed increases self in the same rate.

Version 2: Machine feeding for through holes (MFT)

- Burnish the through holes.

- It can be used on all kind of machining production machines.

- Feed rate = 0,05 - 0,3 mm/rev. per roller

Version 3: Machine feeding for blind holes (MFB)

- Burnish the blind holes up to end. It can be used for also through holes and semi-blind holes.

- It can be used on all kind of machining production machines.

- Feed rate = 0,05 - 0,3 mm/rev. per roller

Technical Features

- Circumferential speed (Vc) for all versions = max. 250 m/min.

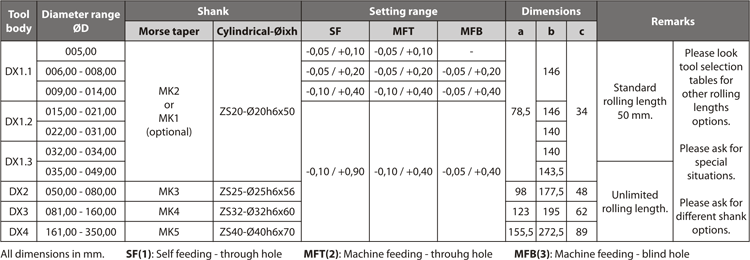

- Tools can be adjustable 0,15 - 1 mm according to type.

- Has a 0,002 mm precise adjustment mechanism.

- Can burnish the holes up to H8-H9 tolerance with one adjustment.

- Burnishing all kinds of metallic materials up to the tensile strength of 1400N/mm² and to the hardness 42-45 HRC.

- Easy setting, long using life, low spare parts consumption. Every kind of spare part can be provided by YAMASA.

Tool Structure

- Tool consist of a burnishing head and a body which has a precision adjustment mechanism.

- Burnishing head consist of a cage, cone and rollers. In the same time, these are consumables.

- It is possible to mount on the same type body the roller heads in different diameter.

- There are cylindrical and morse taper shank choices are available for machine connection (see table).

Bu sayfaya girebilmeniz için 18 yaşından büyük olmanız gerekmektedir.

18 yaşından büyük müsünüz?

You have to be over 18 to enter this page.

Are you over 18?